[Image: The new plastic geology, photographed by Patricia Corcoran, via Science].

[Image: The new plastic geology, photographed by Patricia Corcoran, via Science].

Incredibly, a “new type of rock cobbled together from plastic, volcanic rock, beach sand, seashells, and corals has begun forming on the shores of Hawaii,” Science reports.

This new rock type, referred to as a “plastiglomerate,” requires a significant heat-source in order to form, as plastiglomerates are, in effect, nothing but molten lumps of plastic mixed-in with ambient detritus. Hawaii with its coastal and marine volcanoes, offers a near-perfect formational landscape for this artificially inflected geology to emerge—however, Patricia Corcoran, one of the discoverers of these uncanny rocks, thinks we’ll likely find them “on coastlines across the world. Plastiglomerate is likely well distributed, it’s just never been noticed before now, she says.”

We’ve been surrounded by artificial geologies all along.

But is it really geology? Or is it just melted plastic messily assembled with local minerals? Well, it’s both, it seems, provided you look at it on different time-scales. After heavier chunks of plastiglomerate form, fusing with “denser materials, like rock and coral,” Science writes, “it sinks to the sea floor, and the chances it will become buried and preserved in the geologic record increase.” It can even form whole veins streaking through other rock deposits: “When the plastic melts, it cements rock fragments, sand, and shell debris together, or the plastic can flow into larger rocks and fill in cracks and bubbles,” we read.

It doesn’t seem like much of a stretch to suggest that our landfills are also acting like geologic ovens: baking huge deposits of plastiglomerate into existence, as the deep heat (and occasional fires) found inside landfills catalyzes the formation of this new rock type. Could deep excavations into the landfills of an earlier, pre-recycling era reveal whole boulders of this stuff? Perhaps.

The article goes on to refer to the work of geologist Jan Zalasiewicz, which is exactly where I would have taken this, as well. Zalasiewicz has written in great detail and very convincingly about the future possible fossilization of our industrial artifacts and the artificial materials that make them—including plastic itself, which, he suggests, might very well leave traces similar to those of fossilized leaves and skeletons.

In a great essay I had the pleasure of including in the recent book Landscape Futures, Zalasiewicz writes: “Plastics, which are made of long chains of subunits, might behave like some of the long-chain organic molecules in fossil plant twigs and branches, or the collagen in the fossilized skeletons of some marine invertebrates. These can be wonderfully well preserved, albeit blackened and carbonized as hydrogen, nitrogen and oxygen are driven off under the effect of subterranean heat and pressure.” Plastiglomerates could thus be seen as something like an intermediary stage in the long-term fossilization of plastic debris, a glimpse of the geology to come.

Ultimately, the idea that the stunning volcanic beaches of Hawaii are, in fact, more like an early version of tomorrow’s semi-plastic continents and tropical archipelagoes is both awesome and ironic: that an island chain known for its spectacular natural beauty would actually reveal the deeply artificial future of our planet in the form of these strange, easily missed objects washing around in the sand and coral of a gorgeous beach.

(Spotted via Rob Holmes. Vaguely related: War Sand).

[Image: Neri Oxman’s otherwise unrelated “Silk Pavilion” at MIT; photo by Steven Keating via Wired].

[Image: Neri Oxman’s otherwise unrelated “Silk Pavilion” at MIT; photo by Steven Keating via Wired].

[Image: The new plastic geology, photographed by

[Image: The new plastic geology, photographed by

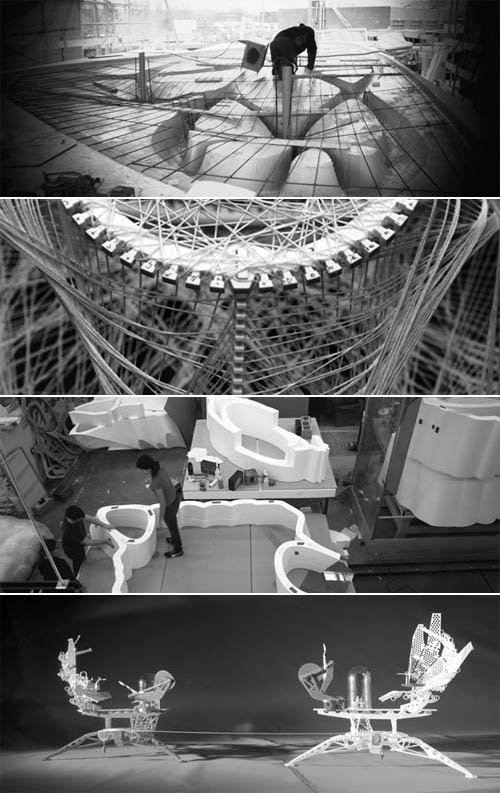

[Images: (top to bottom) Projects by Asbjørn Søndergaard , Marta Malé-Alemany, Wes Mcgee, and Nat Chard, courtesy of

[Images: (top to bottom) Projects by Asbjørn Søndergaard , Marta Malé-Alemany, Wes Mcgee, and Nat Chard, courtesy of  [Image: A project by Amanda Levete Architects, courtesy of

[Image: A project by Amanda Levete Architects, courtesy of

[Image: The

[Image: The  [Image: The

[Image: The  [Image: The

[Image: The

[Images: The

[Images: The  [Images: The

[Images: The