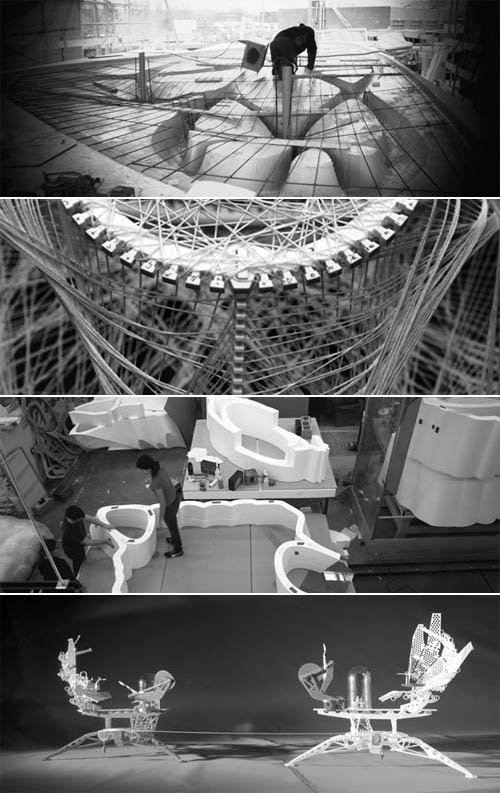

[Images: (top to bottom) Projects by Asbjørn Søndergaard , Marta Malé-Alemany, Wes Mcgee, and Nat Chard, courtesy of Fabricate].

[Images: (top to bottom) Projects by Asbjørn Søndergaard , Marta Malé-Alemany, Wes Mcgee, and Nat Chard, courtesy of Fabricate].

Fabricate is the place to be in London next month, when a group of “pioneers in design and making within architecture, construction, engineering, manufacturing, materials technology and computation” all descend on the Bartlett School of Architecture for a two-day exchange of techniques and ideas.

As the conference organizers explain, topics “will include: how digital fabrication technologies are enabling new creative and construction opportunities, the difficult gap that exists between digital modeling and its realization, material performance and manipulation, off-site and on-site construction, interdisciplinary education, economic and sustainable contexts.”

[Image: A project by Amanda Levete Architects, courtesy of Fabricate].

[Image: A project by Amanda Levete Architects, courtesy of Fabricate].

Speakers include Philip Beesley, Neri Oxman, Nat Chard, Mette Ramsgard Thomsen, Matthias Kohler, Mark Burry, and many more. Follow their Twitter feed for further updates, and check out the conference website for information on attending.

In this context, I’m reminded of the “giant 3D loom” that’s been invented to “weave” parts for a “supercar.” More specifically, it’s “a high-tech circular loom, guided by lasers, that can weave 3D objects.”

The “supercar” in question, made by Lexus, “is being used as a test bed for newly-designed parts made from carbon fibre and plastic. Compared to steel or aluminium, it makes the car stronger and lighter but producing these components is much more time-consuming: only one car is currently being assembled per day.”

According to Lexus, 3D weaving technology reduces the volume of materials used by 50 per cent and increases their strength. The automated process should also make it easier to produce a large volume of parts in the future. They hope to use this machine, and other carbon fibre manufacturing technologies, to create more efficient cars.

Or more efficient buildings.

Get one of these circular superlooms in London for the Fabricate conference; Lexus can offer some corporate sponsorship to make it worthwhile, and you can weave a new structure in its entirety each day, unleashing this hypnotic race of machine-spiders and their laser-assisted loom.

Also, check out this video:

New industrial shapes emerge from a slow cyclone of threaded metal. Future silks for future objects.

In any case, if you’re in London on 15-16 April, be sure to check out Fabricate, and, if you see the organizers, tell them you read about it on BLDGBLOG.

Geoff,

Thank you for posting about fabrication. I do hope you continue to cover this topic as it is of growing interest to the design, fabrication, manufacturing, and building industries.

Will you be at the upcoming lecture at SCI-arc on March 25-26th on composites and digital fabrication? The lecture is free but requires registration. Many notable academic and industry innovators will be there.

http://www.sciarc.edu/lectures.php?id=1902

The Economist magazine featured 3D printing on the cover in February.

http://www.economist.com/node/18114327

And cam/cnc fabrication certainly merits more coverage than it is getting in the architectural press, which remains mired in arguments over cad authoring applications and defining geometry rather than reinventing the design and delivery process (referred to by some in the academic community as Integrated Design and Delivery Solutions).

http://www.aecbytes.com/viewpoint/2011/issue_58.html

In the building industry, digital fabrication is far more common in Europe and Japan than in North America. I am definitely interested in making introductions should you be interested.

Greg